UV-326

Light Stabilizer

UV-326 is especially suited for polyolefins and cold cured polyesters. It has a wide range of indirect food approvals in polyolefins. It has a low volatility at high temperatures and high resistance to thermal degradation and can therefore be used without significant loss or decomposition in the polyolefin compounding and molding processes. In the use for the UV protection of polyester resins, UV-326 does not form colored complexes with the metallic salts used for the curing process of these resins.

Poloyefins: It is recommended to use UV-326 with a HALS type light stabilizer system for best results. The recommended concentrations range for PP applications from 0.1 to 0.5%, for PE applications from 0.1 to 0.4%.

Polyester resins: The recommended levels for normal polyester resins range from 0.2 to 0.3%, while for chlorinated, flame retardant polyester resins the recommendation is 0.5%.

Paints and varnishes: UV-326 use levels depend on the thickness of the dry coating and the final application. Typical use levels for polyester varnish from 0.25% to 0.3% (200-300μm dry coating thickness), and for nitro fiber varnish from 0.5% to 1.0% (60-120μm dry coating thickness).

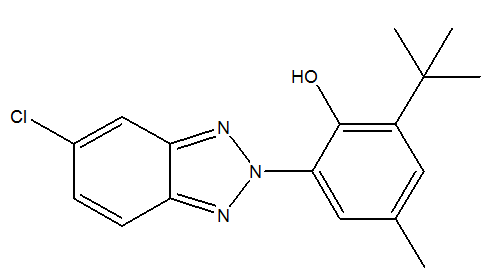

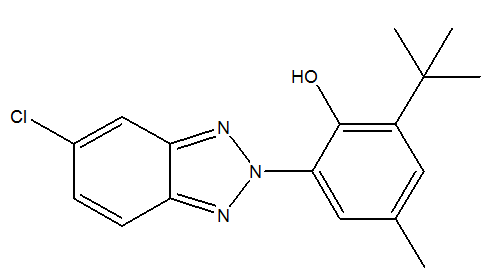

2-(5-Chloro-2H-benzotriazol-2-yl)-6-(1,1-dimethylethyl)-4-methylphenol

CAS# 3896-11-5

TYPICAL PROPERTIES

|

Property |

Typical Result |

|

Appearance |

Slightly yellow powder |

|

Molecular Weight g/mol |

315.8 |

|

Melting Range, °C |

138-141 |

|

Flash Point, °C |

238 |

|

Specific Gravity, g/cm3 |

1.32 |

|

Bulk Density, g/l |

130-200 |

STORAGE:Keep containers tightly closed in a dry, cool and well-ventilated place。

PACKAGING:20KG/BAG