Irganox B215 and B225 specification

Product Description: Irganox B215 and B225 is a mixture of Irganox 168 and Irganox 1010.

Key Features & Benefits -Maintain the initial melt flow rate

- small color change

- improve long-term thermal stability

The organophosphite Irganox 168 has a low volatility and is particularly resistant to hydrolysis, protecting the organic polymer from oxidation during processing. Irganox 1010 provides both processing stability and long-term thermal stability to prevent thermal degradation during use.

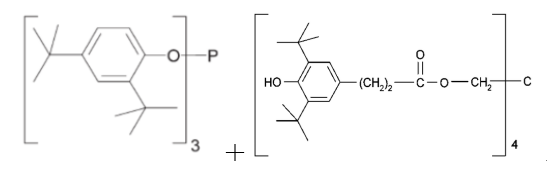

Chemical Composition: Tris(2,4-di-tert-butylphenyl)phosphite and Pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate).

+

Properties:

Typical Properties: Appearance white, free-flowing powder

CAS number: Irganox 168[31570-04-4], Irganox 1010[6683-19-8]

Density (bulk): 530-630g/l

Applications

Irganox B215 can be applied in polyolefins, such as polyethylene, polypro pylene, polybutene and olefin copolymers such as ethylene-vinylacetate copolymers. Also, its use is recommended for the processing of polymers such as polyacetals, polyamides and polyurethanes, polyesters, PVC, sty rene homo- and copolymers, ABS, elastomers such as butyl rubber (IIR), SBS, SEBS, EPM and EPDM as well as other synthetic rubbers, adhesives, natural and synthetic tackifier resins, and other organic substrates.